Seri Pendingin Minyak Jenis Tube Gl

Produk iki diprodhuksi dening perusahaan kami sing nggabungake basis teknologi canggih lan eksternal lan kerajinan. Materi pipa pertukaran-pertukaran, nganggo pipa tembaga abang pucuk rendah, nggunakake struktur papan pemutus arus melintang, papan turbulensi lan kerajinan mekanisme maju sing berkembang, nduweni fitur struktur novel, dimensi cilik, cahya efek pertukaran panas lan uga ora suwe. Produk iki minangka adhem efisiensi jinis lan efisiensi higli anyar, umume digunakake ing sistem hidrolik lan minyak viskositas rendah kanggo adhem minyak kerja kanthi suhu sing ditemtokake. Dadi fasilitas pendinginan Ideal sing bisa digunakake kanthi akeh ing adhem peralatan hidrolik ing perdagangan kayata industri kimia, tenaga listrik, industri metalurgi, tambang lan industri ringan.

Saben seri sing adhem duwe akeh spesifikasi lan jinis sing cocog karo kebutuhan saben pangguna. Kajaba produk utama sing dikenalake ing manual operasi, perusahaan uga bisa nggawe macem-macem jinis khusus kanggo para pelanggan miturut sarat.

Pendingin minyak jinis tabung

C : tabung finned

L : pipa gundhul

Seri No.

Area pendinginan nominal: m2

Produk Khusus: B: Shell Steel Stainless

H: Kanggo banyu adhem yaiku banyu laut

Inlet lan outlet minyak (banyu) ukurane beda, mangga tandhani kanthi langsung

Liyane syarat FB- port

Standar bisa ngilangi

Cara nginstal: L-vertikal; jinis non-horisontal

Tekanan nominal: A = 1.6MPa (ngilangi)

DATA TEKNIKAL

| Viskositas medium | Suhu mlebu minyak | Suhu mlebu banyu | Pendinginan minyak | Tekanan ilang | Aliran rasio minyak karo banyu | W / M2 - ° C

Faktor pertukaran panas |

|

|

Sisih minyak |

Sisih banyu | ||||||

| N68 | 55 ± 1 | W30 | N8 | W0.1 | <0,05 | 1: 1 | N350 |

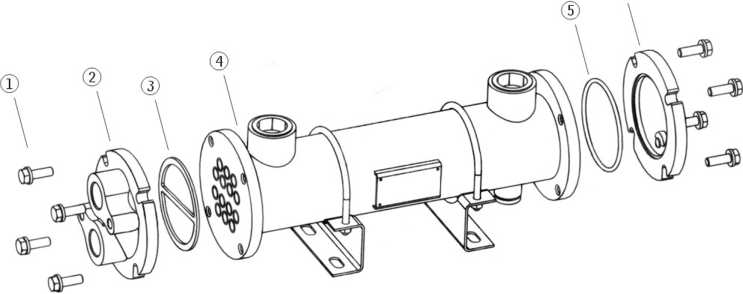

SIZE MOUNTING

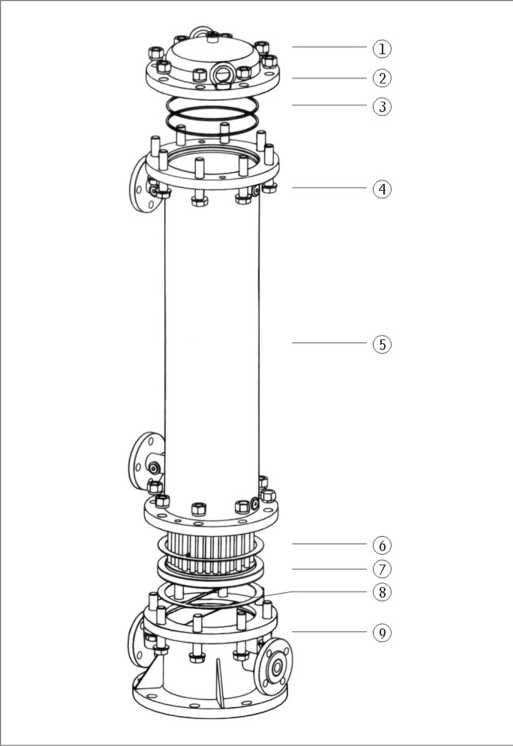

| Nomer | Jeneng | Cathetan |

| 1 | Samberan | |

| 2 | Tutup | |

| 3 | Segel | Ngagem bagean |

| 4 | Omah | |

| 5 | O-ring | Ngagem bagean |

| 6 | Tutup |

|

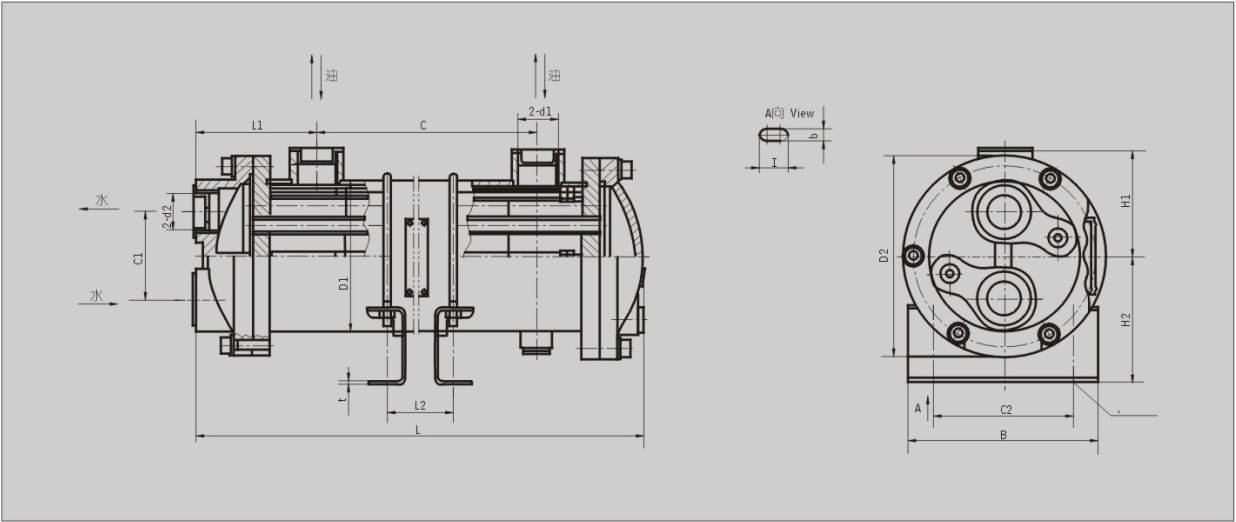

Model |

L |

C |

L1 |

Hl |

H2 |

DI |

D2 |

Cl |

C2 |

B |

L2 |

t |

nb x Aku |

dl |

d2 |

Aliran minyak L / mnt |

Bobot (Kg) |

| GLC1-0.4 | 390 | 240 | 145 |

20 |

7 |

||||||||||||

| GLC1-0.6 | 555 | 405 | 310 |

30 |

9 |

||||||||||||

| GLC1-0.8 | 685 | 532 |

80 |

64 |

75 |

80 |

120 |

50 |

65 |

105 |

435 |

2 | 4-10 x 20 | G1 |

G3 / 4 |

40 |

10 |

| GLC1-1 | 815 | 665 | 570 |

45 |

12 |

||||||||||||

| GLC1-1.2 | 955 | 805 | 715 |

50 |

14 |

||||||||||||

| GLC2-1.3 | 555 | 375 | 225 |

52 |

17 |

||||||||||||

| GLC2-1.7 | 680 | 500 | 350 |

57 |

20 |

||||||||||||

| GLC2-2.1 | 815 | 635 |

485 |

62 |

24 |

||||||||||||

|

94 |

85 |

100 |

121 | 160 |

70 |

110 |

150 |

2 | 4-10 x 20 | G1 | G1 | ||||||

| GLC2-2.6 | 955 | 775 | 630 |

70 |

28 |

||||||||||||

| GLC2-3 | 1105 | 925 | 780 |

80 |

33 |

||||||||||||

| GLC2-3.5 | 1265 | 1085 | 935 | 85 | 37 | ||||||||||||

| GLC3-4 | 820 | 570 | 380 |

75 |

45 |

||||||||||||

| GLC3-5 | 970 | 720 | 530 | Gll / 2 |

Gll / 4 |

100 |

51 |

||||||||||

| GLC3-6 | 1120 | 870 | 680 | 125 |

57 |

||||||||||||

| GLC3-7 | 1290 | 1040 | 850 | 150 |

64 |

||||||||||||

|

132 |

115 |

151 |

162 | 220 |

100 |

160 |

205 |

3 | 4-15 x 25 | ||||||||

| GLC3-8 | 1450 | 1200 |

1010 |

175 |

70 |

||||||||||||

| GLC3-9 | 1610 | 1360 | 1170 | 200 |

76 |

||||||||||||

| GLC3-10 | 1780 | 1530 | 1340 | G2 |

Gll / 2 |

225 |

83 |

||||||||||

| GLC3-11 | 1960 | 1710 |

1520 |

250 |

90 |

||||||||||||

| GLC4-13 | 1355 | 985 | 745 | 230 |

132 |

||||||||||||

| GLC4-15 | 1515 | 1145 | 905 | 260 |

142 |

||||||||||||

| GLC4-17 | 1675 | 1305 | 1065 | 300 |

153 |

||||||||||||

| GLC4-19 | 1845 | 1475 | 1235 | 330 |

165 |

||||||||||||

|

197 |

160 |

180 |

219 | 310 |

120 |

200 |

280 |

8,5 |

4-22 x 30 | G2 | G2 | ||||||

| GLC4-21 | 2025 | 1655 | 1415 | 360 |

177 |

||||||||||||

| GLC4-23 | 2195 | 1825 | 1585 | 400 |

188 |

||||||||||||

| GLC4-25 | 2375 | 2005 | 1765 | 430 |

200 |

||||||||||||

| GLC4-27 | 2545 | 2175 | 1935 | 470 |

212 |

DATA TEKNIKAL

|

Viskositas medium |

Suhu mlebu minyak |

Suhu mlebu banyu |

Pendinginan minyak |

Tekanan ilang |

Aliran rasio minyak karo banyu |

W / M2 - ° C Faktor pertukaran panas |

|

|

Sisih minyak |

Waterside |

||||||

|

N68 |

50 ± 1 |

W30 |

N8 |

W0.1 |

<0,05 |

1: 1.5 |

N230 |

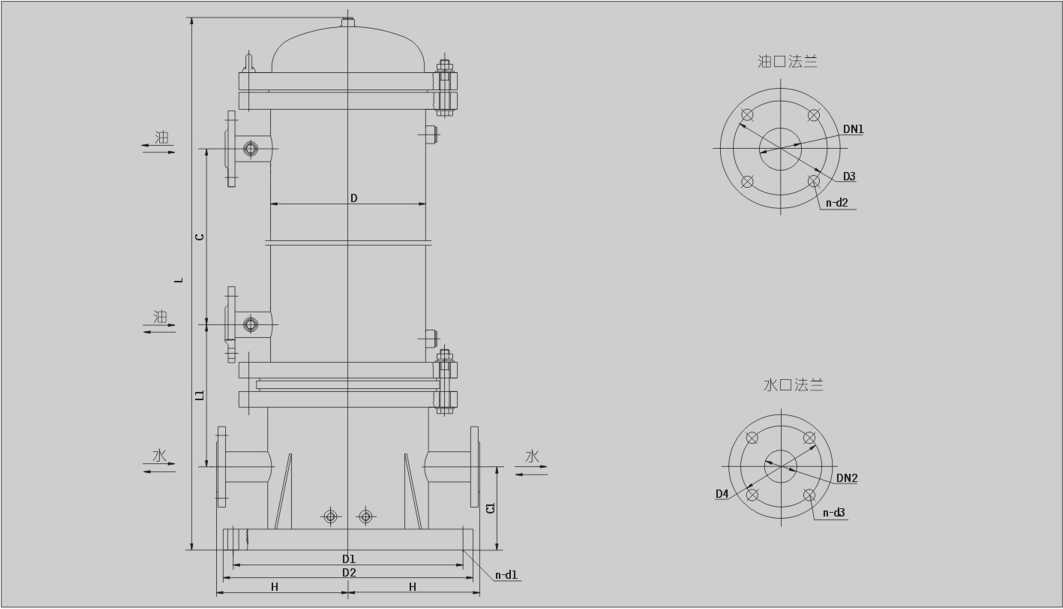

SIZE MOUNTING

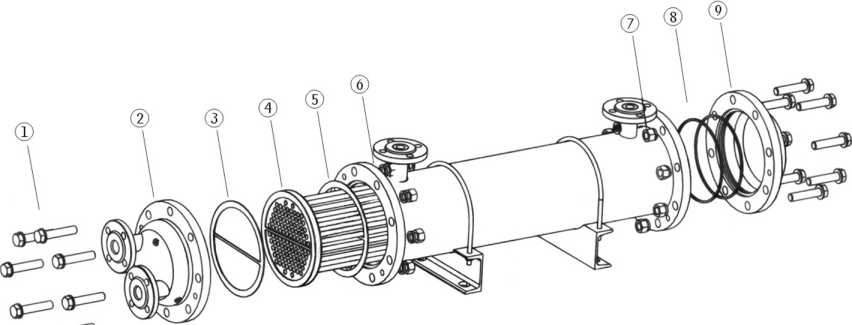

|

Nomer |

Jeneng |

Cathetan |

| 1 | Samberan | |

| 2 | Tutup | |

| 3 | Segel | Ngagem bagean |

|

4 |

Perangan pertukaran panas | |

| 5 | Segel | Ngagem bagean |

| 6 | omah | |

| 7 | Kacang | |

| 8 | Segel | Ngagem bagean |

| 9 | Tutup |

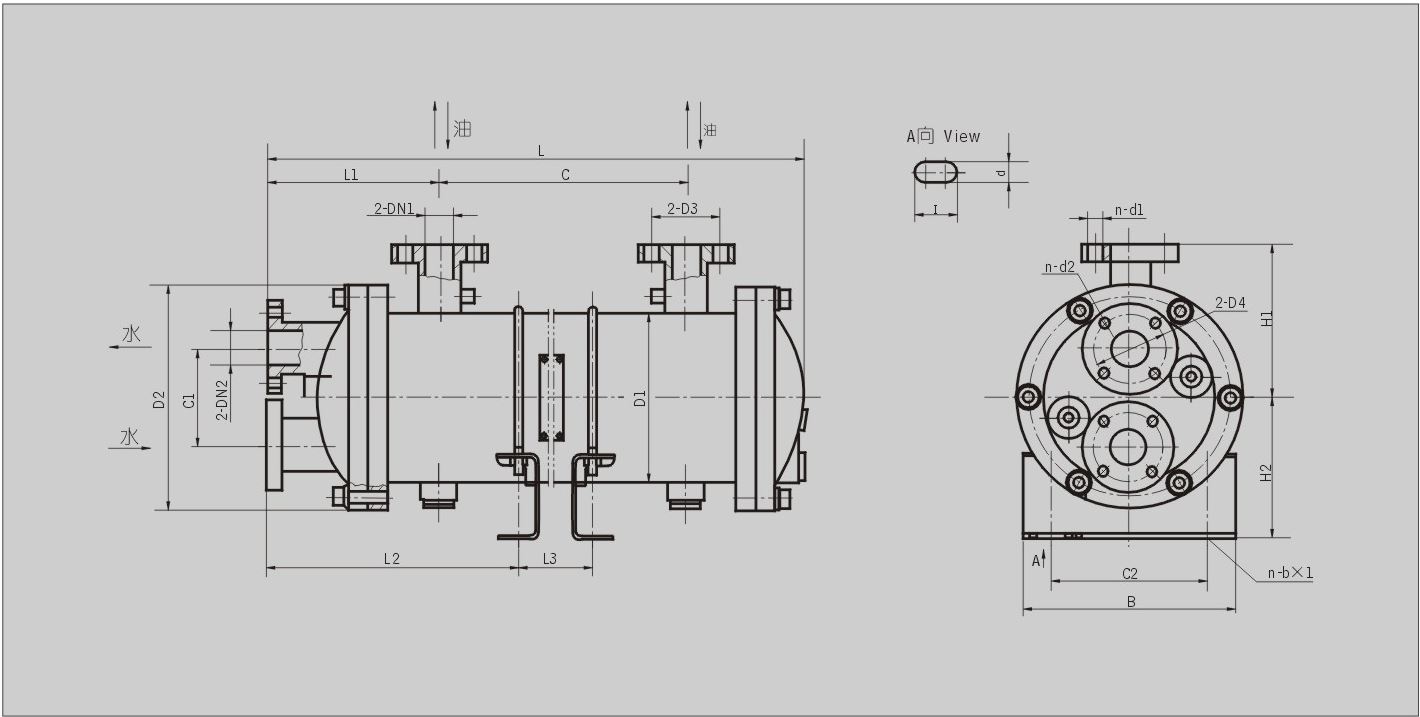

| Model | L |

C |

L1 |

Hl |

H2 | DI | D2 | Cl | C2 | B |

L2 |

L3 |

D3 |

D4 |

n-dl |

n-d2 |

nb x Aku | DN1 | DN2 |

Aliran minyak L / min) |

Bobot (Kg) |

| GLL3-4

GLL3-5 GLL3-6 GLL3-7 |

1150

1450 1750 1980 |

682

982 1282 1512 |

265 | 190 | 180 | 219 | 310 | 140 | 200 | 280 | 367 | 485 | 100 |

100 |

4-Φ17.5 | 4- Φ17.5 | 4-22 x 30 |

32 |

32 |

75 100 125 150 |

108 123 138 150 |

| 785 | |||||||||||||||||||||

|

1085 |

110 |

40 |

|||||||||||||||||||

|

1385 |

|||||||||||||||||||||

| GLL4-12

GLL4-16 GLL4-20 GLL4-24 GLL4-28 |

1555

1960 2370 2770 3180 |

960

1365 1775 2175 2585 |

345 | 262 | 232 | 325 | 435 | 200 | 300 | 370 | 497 |

660 |

145 | 145 | 4-Φ17.5 | 4-Φ17.5 | 4-22 x 30 |

65 |

65 |

250

350 450 550 650 |

238 300 360 455 536 |

|

1065 |

|||||||||||||||||||||

|

1475 |

|||||||||||||||||||||

|

1885 |

160 | 8-Φ17.5 |

80 |

||||||||||||||||||

|

2295 |

|||||||||||||||||||||

| GLL5-35

GLL5-40 GLL5-45 GLL5-50 GLL5-60 |

2480

2750 2990 3260 3800 |

1692

1962 2202 2472 3012 |

500 | 315 | 293 | 426 | 535 | 235 | 400 | 500 | 730 |

1232 1502 1772 |

180 | 180 | 8-Φ17.5 | 8-Φ17.5 | 4-22 x 30 |

100 |

100 | 625

750 875 1000 1250 |

570 640 745 825 955 |

|

2042 |

210 |

125 |

|||||||||||||||||||

|

2582 |

|||||||||||||||||||||

| GLL6-80

GLL6-100 GLL6-120 |

3160

3760 4360 |

2015

2615 3215 |

700 | 500 | 408 | 616 | 780 | 360 | 550 | 700 | 935 |

1555 |

295 | 295 |

8-Φ22 |

8-Φ22 | 4-25 x 32 |

200 |

200 | 1500

2000 2500 |

1617 1890 2163 |

|

2155 |

|||||||||||||||||||||

|

2755 |

DATA TEKNIKAL

|

Viskositas medium |

Suhu mlebu minyak |

Suhu mlebu banyu |

Pendinginan minyak |

Tekanan ilang |

Aliran rasio minyak karo banyu |

W / M2 - ° C Faktor pertukaran panas |

|

|

Sisih minyak |

Waterside |

||||||

|

N68 |

50 ± 1 |

W30 |

N8 |

W0.1 |

<0,05 |

1: 1.5 |

N230 |

SIZE MOUNTING

| Number | Name | Note |

| 1 | Nut | |

| 2 | Cap | |

| 3 | Seal | Wbagean mangan |

| 4 | Bolt | |

| 5 | Housing | |

| 6 | Segel | Wbagean mangan |

| 7 | Hmangan bagean ijol-ijolan | |

| 8 | Segel | Wbagean mangan |

| 9 | Cap |

|

Model |

L |

C |

L1 |

Cl |

H |

D |

DI |

D2 |

D3 |

D4 |

DN1 | DN2 |

n-dl |

n-d2 |

n ‡ d3 |

Arus minyak (L / mnt) |

Bobot (kg) |

| GLL3-4L | 1220 | 682 |

100 |

32 |

75 |

125 |

|||||||||||

| GLL3-5L | 1520 | 982 | 320 | 100 | 190 | 219 | 320 | 360 | 100 |

32 |

8-Φ24 |

4-Φ17.5 | 4-Φ17.5 | 100 |

140 |

||

| GLL3-6L | 1820 | 1282 |

110 |

40 | 125 |

155 |

|||||||||||

| GLL3-7L | 2050 | 1512 | 150 |

165 |

|||||||||||||

| GLL4-12L | 1630 | 960 | 250 |

268 |

|||||||||||||

| GLL4-16L | 2035 | 1365 |

145 |

65 | 4-Φ17.5 | 350 |

330 |

||||||||||

| GLL4-20L | 2445 | 1775 | 400 | 130 | 262 | 325 | 440 | 480 | 145 |

65 |

8-Φ24 |

4-Φ17.5 | 450 |

390 |

|||

| GLL4-24L | 2845 | 2175 |

160 |

80 | 8-Φ17.5 | 550 |

485 |

||||||||||

| GLL4-28L | 3255 | 2585 | 650 |

566 |

|||||||||||||

| GLL5-35L | 2545 | 1692 |

180 |

100 | 625 |

605 |

|||||||||||

| GLL5-40L | 2815 | 1962 | 750 |

660 |

|||||||||||||

| GLL5-45L | 3065 | 2202 | 530 | 180 | 315 | 426 | 570 | 620 | 180 | 100 |

8-Φ28 |

8-Φ17.5 | 8-Φ17.5 | 875 |

781 |

||

| GLL5-50L | 3335 | 2472 |

210 |

125 | 1000 |

860 |

|||||||||||

| GLL5-60L | 3875 | 3012 | 1250 |

960 |

|||||||||||||

| GLL6-80L | 3170 | 2015 | 1500 | 1630 | |||||||||||||

|

GLL6-100L |

3770 | 2615 | 690 | 215 | 500 | 616 | 800 | 870 |

295 |

295 | 200 | 200 |

8-Φ35 |

8-Φ22 |

8-Φ22 |

2000 | 1900 |

|

GLL6-120L |

4370 | 3215 | 2500 | 2175 |

1. Metode petungan

(1) Wilayah transfer panas A (m2) sing dibutuhake

QA = Lengan -K

⑵ Jumlah panas : Q (Kca l / h)

Q = (H-T2) CW = (t2-tl) C , W , <2 = Jumlah panas (kca l / h) k = Koefisien transfer panas (kca l / m2h ° C) Atiii = Tegese beda suhu (° C)

Antarane : D 1 = suhu minyak inlet ° C 2 = Ekspor suhu minyak ° C。 = Impor suhu banyu ° C

2 = Ekspor suhu banyu ° CC = Panas minyak khusus (kca l / kg 。。 Panas banyu tartamtu (kca l / kg ° C)

W = Aliran minyak (kg / h) '= Aliran banyu (kg / h)

(3) Rata-rata prabédan suhu kiwa T m (° C)

(4) Koefisien transfer panas: K (kca l / m2h ° C)

a) Nalika aliran banyu adhem sithik lan viskositas minyak sing digunakake dhuwur, K = 200 dijupuk ;

b) Umume njupuk K = 250 nalika digunakake lenga ;

c) Nalika aliran banyu adhem gedhe lan viskositas minyak sing digunakake kurang, K = 350 ~ 400 dijupuk0 ;

2. Estimasi

|

Tenaga motor KW |

7.5-10 |

10-15 |

15-20 |

20-30 |

30-40 |

40-75 |

75-100 |

100-120 |

120-150 |

150-200 |

| Area pendinginan sing dipilih (nf) |

0,4 0,6 |

0,8 1.0 |

1.2 1.3 |

1.7 2.1 |

2.6 3 |

3.5 4 |

5 6 |

7 8 |

8 9 |

10 11 |